Baseball has captivated sports enthusiasts for over a century. It may seem like a simple piece of equipment. The composition of a baseball bat can significantly impact a player’s performance on the field, so the question arises: What are baseball bats made of?

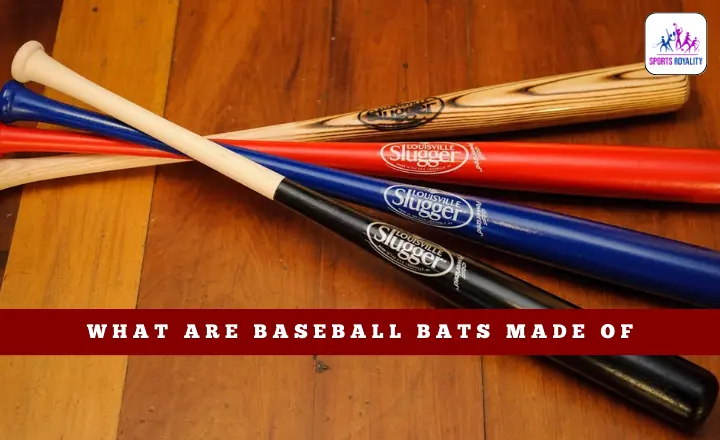

From traditional wooden bats that evoke nostalgia and tradition to modern composite bats that push the boundaries of technology, the materials used in their construction play a crucial role in determining power, speed, and overall success at the plate.

In this article, we will dive into the fascinating world of baseball bats and explore what they’re made of and how these materials have evolved throughout history.

What are Baseball Bats Made Of? History of Baseball Bats

They are carefully crafted instruments designed to enhance a player’s performance on the field. While most people consider wood the traditional material, many options are available today.

We see sleek and lightweight composite bats on the field; it was only sometimes so. In the early days of baseball in the mid-19th century, players would fashion their bats from whatever materials they could find, often crudely shaped and heavy.

One exciting aspect of this early era was that there were no restrictions on bat size or shape. This led to various experimental designs, ranging from long and thin fungo-style bats intended for practice to short and stout clubs for gameplay.

As baseball gained popularity, players began seeking specialised bat makers, and equipment companies emerged to meet the demand.

Wood Bats

Until 1884, players were responsible for crafting their bats out of wood. The 1800s saw a surge in resourcefulness among baseball players as they honed their skills on the field and in the workshop.

The process of making a bat was no easy feat. Players would carefully select the type of wood most suited to their swing and weight preferences. Hickory and ash were popular choices due to their durability and flexibility.

The bat-making process involved hand shaping and carving the wood, adjusting dimensions based on personal preference, and applying various finishes to ensure longevity.

While today’s professional players rely on manufacturers to provide them with quality bats, it is fascinating to consider how these early pioneers took matters into their own hands.

The craftsmanship that went into creating each wooden bat added an extra layer of connection between player and instrument, fostering a sense of ownership that might be missing in modern-day baseball.

Different types of wood are used to manufacture MLB bats. Here are they are:

Ash Bats

Ash bats have stood the test of time as the go-to choice for professional baseball players. Their lightweight yet sturdy nature gives players a slight advantage in bat speed compared to other materials. The quickness and power generated with an ash bat are unparalleled, making it a preferred option for many hitters.

What sets ash bats apart from their counterparts is their unique flexibility. Unlike maple bats, known for their hardness and durability, ash bats offer more give and flex upon impact. This allows players to whip the bat through the strike zone with incredible speed, generating maximum power and distance on each hit.

Ashwood has a natural moisture content that helps absorb shock vibrations upon contact with the ball. This reduces stinging sensations felt in a hitter’s hands and prevents unnecessary stress on muscles and joints during repetitive swinging motions.

Maple Bats

Maple bats have gained tremendous popularity among long ball hitters in baseball due to their stiffness. Unlike other types of wood, maple bats offer less flexibility, which allows for more power and distance when hitting the ball.

This stiffness provides a solid and steady contact with the ball, giving hitters an advantage when sending it sailing over the fences.

A fascinating perspective about maple bats is that they are considered a status symbol among big-league hitters. Many professional players opt for these high-end bats as they are associated with strength and power at the plate.

Birch Bats

While maple bats are known for their hardness and ash bats for their lightness, birch bats offer the best of both worlds. The density of the birch wood allows for a solid hit while providing some give to absorb shock.

Birch bats’ distinct advantage is their ability to endure multiple hits without easily breaking. This is particularly beneficial for power hitters who drive balls at high speeds and consistently make contact on the bat’s barrel.

Birch bats, with their robust structure, can withstand the impact and deliver powerful hits time after time.

Bamboo Bats

Bamboo bats have gained popularity in baseball for their durability and performance. Made from multiple layers of bamboo stalks pressed together, these bats offer a unique combination of strength and flex.

While they may not be allowed in professional MLB games due to regulations categorising bamboo as a composite material rather than wood, they are widely used in amateur leagues and practice settings.

The natural fibres in bamboo provide excellent shock absorption, reducing the vibration felt upon contact with the ball. This feature allows players to maintain better control over their swings and minimises the risk of developing hand injuries over time.

Another exciting aspect of bamboo bats is that they can be customised to suit individual preferences. Manufacturers often offer various handle thicknesses and barrel sizes, allowing players to select a comfortable bat that enhances their performance on the field.

Wood Composite Bats

Wood composite bats have quickly gained popularity among baseball and softball players due to their unique advantages over traditional wooden or aluminium bats. One significant advantage is their durability.

Unlike wooden bats, prone to cracking or breaking, wood composite bats are made from a blend of wood fibres and other materials, making them highly resistant to damage.

Another great thing about wood composite bats is their improved performance. These bats offer wood’s flexibility and metal’s stiffness, increasing power and distance when hitting the ball. This makes them suitable for both professional athletes and amateur players looking to enhance their performance on the field.

Metal/Aluminum Alloy Bats

One of the main drawbacks of aluminium bats was their lack of durability. The lightweight and thin design made them prone to denting and bending, especially when hit with high-speed pitches.

This decreased performance over time, as the dents and bends affected the bat’s ability to make solid contact with the ball. Players often had to replace their aluminium bats after just a few seasons, which proved costly for both professional and amateur players.

Advancements in technology have led to the development of aluminium alloy bats that address these durability concerns. By blending aluminium with other materials, such as zinc or copper, manufacturers have created bats that are lighter, stronger, and more resistant to damage.

These new alloy bats have become popular among players due to their enhanced performance and longer lifespan.

Metal aluminium alloy bats have revolutionised the game of baseball by providing players with a lightweight yet durable alternative to traditional wooden bats. With ongoing technological advancements, it will be exciting to see how these alloy bats continue to evolve and shape the future of America’s favourite pastime.

Composite Bats

Composite bats have revolutionised the game of baseball and softball. These bats offer enhanced performance and durability and are Made from different materials, such as carbon fibre, fibreglass, or Kevlar.

The composite construction allows for greater flexibility and a trampoline effect upon contact with the ball, resulting in increased power and distance. This technology has certainly changed the dynamics of the game.

Composite bats also contribute to player safety. With their advanced technology and construction techniques, these bats help minimise injuries caused by poor bat-to-ball contacts known as stingers.

Due to their forgiving nature on miss-hits, they reduce the risk of fractures from high-speed impacts when a pitch veers off target unexpectedly. This factor alone has significantly contributed to increasing player confidence at all levels of play.

Hybrid Bats

Hybrid models are made from a mix of materials, typically combining an aluminium barrel with a composite handle. This blend allows for lighter swing weight, fast bat speed, and increased hitting distance.

Hybrid bats can offer both durability and performance. The aluminium barrel provides solid contact with the ball, while the composite handle absorbs more vibration upon contact. This results in less sting on mis-hits and reduced chance of injury for the player.

The alloy portion of the hybrid design helps increase pop off the bat, giving hitters an extra boost when it comes to driving balls deep into outfield gaps or over fences.

Conclusion

Above the content, we have discussed in the reply what are baseball bats made of. Baseball bats are made of various materials, each offering unique benefits and drawbacks. Wood bats, such as those made from ash or maple. Aluminum bats are known for their durability and power. Composite bats offer performance and flexibility but may be more expensive.

Choosing a bat that suits your skill level and playing style is vital regardless of the material used. Next time you step up to the plate, consider the composition of your bat and swing for the fences.

FAQ’s

How long do baseball bats usually last?

The lifespan of a baseball bat depends on usage and care, they can last anywhere from several months to several years.

Can I use any baseball bat in all leagues?

Each league has its rules regarding the types of bats allowed for use. It’s essential to check with your specific league or organization for approved bat guidelines before playing.